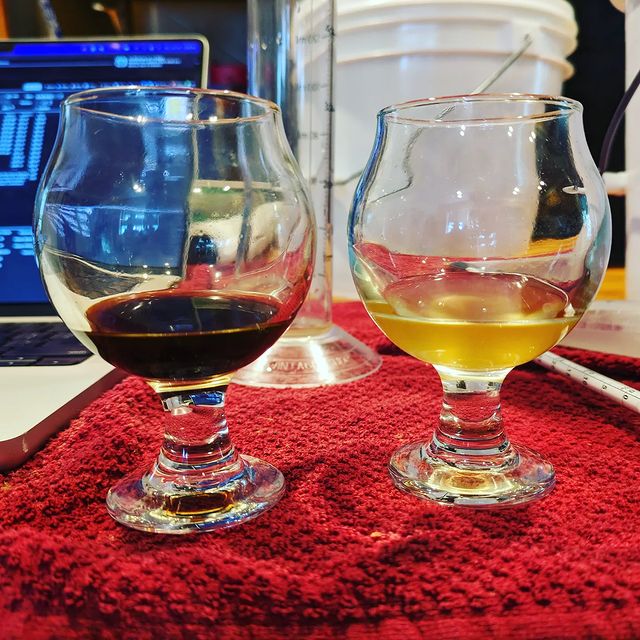

Our next in-person meeting will be on Tuesday, December 12th at Bone Up Brewing Co. in Everett at 7pm. Bring friends and family to say cheers to Bone Up, one last time! More the merrier! Unfortunately, we can’t share homebrew at this meeting. However, feel free bring empty growlers to fill Bone Up beers...